1939

August 26, 1939 is the official date of establishment of the enterprise on the basis of activated carbon.

In the 40s, the plant produced 8 types of activated carbon by the method of steam-gas activation of raw charcoal. It is based on the species of deciduous trees (linden, birch), as well as fruit seeds.

1941

95 workers were awarded the medals "For valiant work in the Great Patriotic war of 1941-1945".

“During the war about 500 people left the plant to fight the enemy. 114 people were killed in battles for the Motherland". (From archive materials)

1942

The mechanization of manual labor began. Since 1942, the plant began a huge construction. During the war years, workshop 3 was built. The production of respiratory protection equipment was organized there. Activated carbon was used in its manufacturing.

1943

Workshop 1 mastered the processing of semi-coke into activated carbon for the iodine industry and non-ferrous metallurgy.

1946

The post-war years were difficult. The country rose from devastation. Plant fulfills plan of 1946 by 123.5%. It began to produce a number of new activated carbons on semi-coke.

1948

The 2nd furnace block was commissioned, and it doubled the capacity of the workshop.

Annual production program was carried out ahead of schedule.

1954

Sector of industry in USSR developed rapidly and there was a lack of coal-based sorbents. Therefore, in 1954 a new workshop 7 appeared at the enterprise.

Gradually, it began the production of granular activated carbons and catalysts.

70s

Production expands, intensive construction of new buildings is held.

In 1975, the workers of the research laboratory developed a fundamentally new technology and introduced it into production. It excluded the use of dangerous sulfuric acid and emissions of toxic nitrogen oxides into the atmosphere.

80s

Employees of the company are actively working to improve the quality of carbons.

All furnace blocks were put into operation and construction of new buildings was completed.

90s

The fall of the Soviet Union did not affect the number of orders for activated carbon. New trademarks of carbons appeared.

To ensure the production of own raw materials, in 1995 the construction of a section for the wood pyrolysis for the production of lump charcoal began.

2000s

Products of the plant are still in demand in the pharmaceutical, chemical, food and other types of industry to prevent the consequences of man-made accidents and natural disasters.

In 2005, an accident occurred at a chemical plant in Jilin (China). In a very short time, the workers of workshop 1 completed a large order. More than 300 tons of SPDK-27D carbon was sent to save the Amur River from nitrobenzene. The cities were saved from a man-made accident.

2006

Reconstruction of the workshop 1 continues.

The production of charcoal briquettes was created, a new crusher was introduced, etc.

Workshop 7 was also a large-scale industrial complex, consisting of many sites and buildings. Perspective equipment was introduced in the workshop. The techniques of Lean production were implemented.

2013

Employees of the scientific and technical service of sorption and chemical technologies of Sorbent JSC together with Perm National Research Polytechnic University won the competition for high-tech production projects.

2018

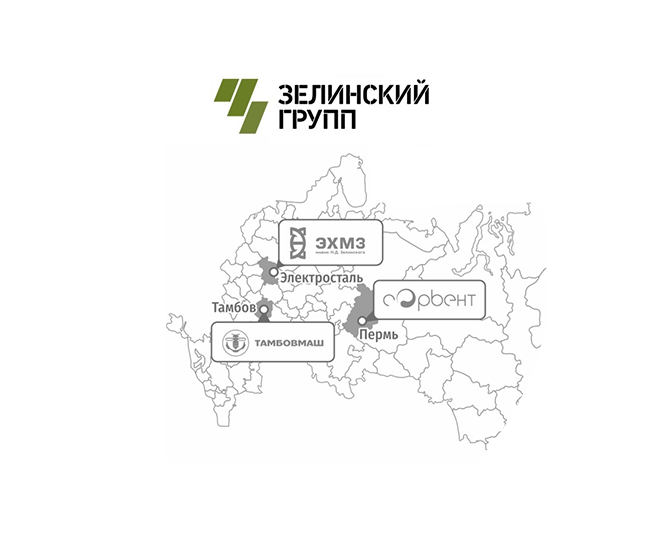

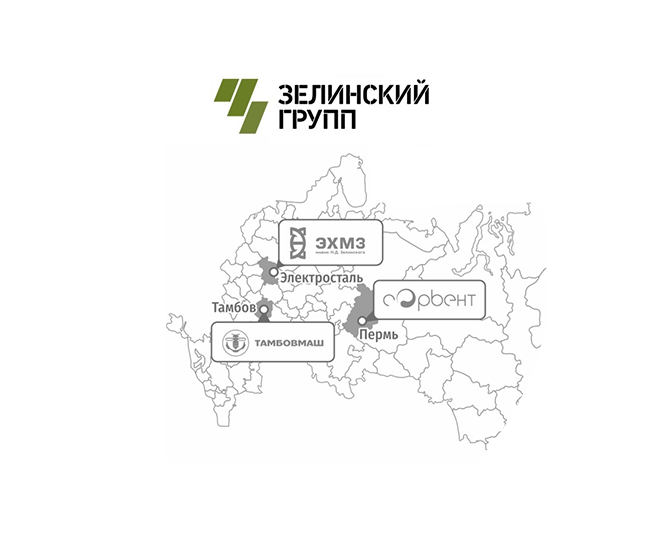

Since 2018, JSC Sorbent has become a part of new brand Zelinsky Group. Philosophy of the brand emphasizes its relationship with the case of the great scientist, Russian chemist Nikolay Zelinsky.